Case Study: Design of a Nano Particle Generator Filter

https://scienceinfo.com/spectroscopy-definition/

The importance of the mass-to-charge ratio, according to classical electrodynamics, is that two particles with the same mass-to-charge ratio move in the same path in a vacuum, when subjected to the same electric and magnetic fields.

Spectroscopy can be found in scientific applications including consideration of how various types of matter emit and absorb radiation, including light.

In this case study, our customer Theris Nano is leader in atomic deposition technologies in areas of nono particle isolation barriers. Spectroscopy is used for diffusion, mobility and separation of ions. This leads us to the need for engineering and electronic circuits to generate electromagnetic fiels to guide filter and form trajectories of ions to their final destinations.

The Physics and intricate details of how Mass Spectroscopy works is best described by Jim Clark here

The need for electronics and engineering

From an engineering perspective, our remit was therefore to develop a control system that would generate a complimenting pair of sinusoids whose attributees of frequency, DC offset and Amplitude could dynamically be programmed in real time. The pair of sinusoids perpendicular to each other as well as perpendicular to the direction of propagation are applied across a pair of rods, resulting in filtration of ions based on their mass/charge ration (m/Z) and guide them along a vacuum trajectory.

System design and modeling

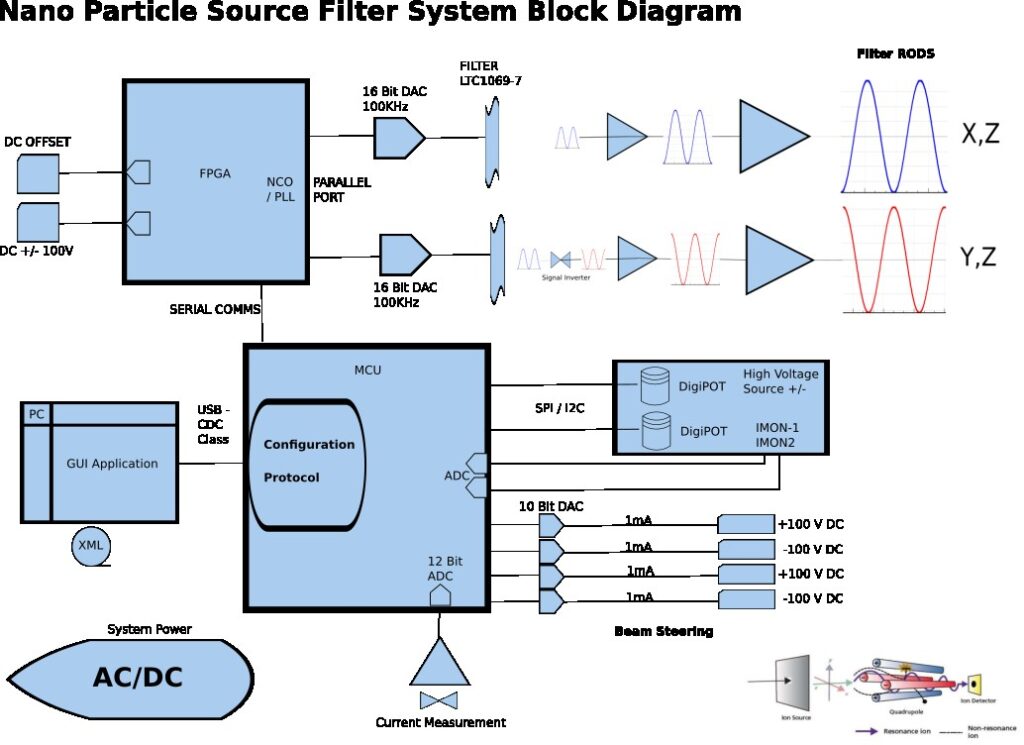

As shown in our block diagram, the salient parts of our system comprises of circuits and interface to control the system dynamically.

To this end we have implemented a USB Serial interface so that our system may be controlled using a custom Terminal Application receiving commands to modify sinusoid attributes and DC offset across our Rods.

The requriement to produce sinusoids with a frequency range of up to 100KHz together with this being a niche product that would only be manufactured in volumes of 10s of units per anuum in the firts instance with a relatively slow ramp up quantities, we have chosen to implement the sinusoid using an Xilinx FPGA. We had initially considered a Numerically Controlled Oscillator implementation but concluded that this could equally be achieved using a look-up table. The FPGA would give us the processing power needed to respond to the generation of a sine wave at the frequency range of interest with minimal lag.

We have chosen a beeefy 32 Bit MCU running on a 100MHz crystal to ensure swift response to various I/O interfaces. As shown, we are using an internal DAC to drive two pairs of Beam Steering Plates, SPI port to communicatee with the FPGA, Serial USB Interface for external Terminal Application and an array of Thermal Management blocks over I2C.

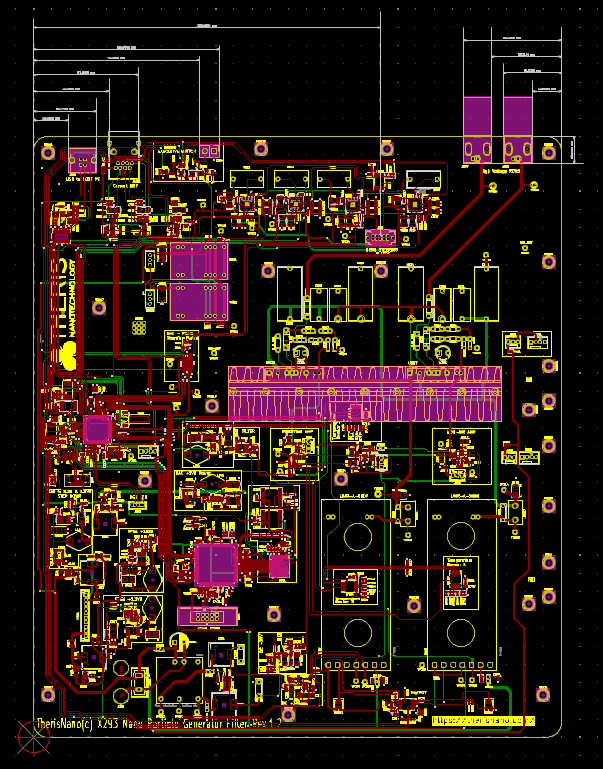

Circuit Design and PCB Layout

You will notice that we’v used KiCad for this design. Our default design suite is Altium Designer but in this case our customer asked from the outset if it could be implemented using KiCad and we obliged. As a side note, whilst not on a par with AD, KiCad is a decent alternative and we’ve had no issues working with and implenting this project with it.

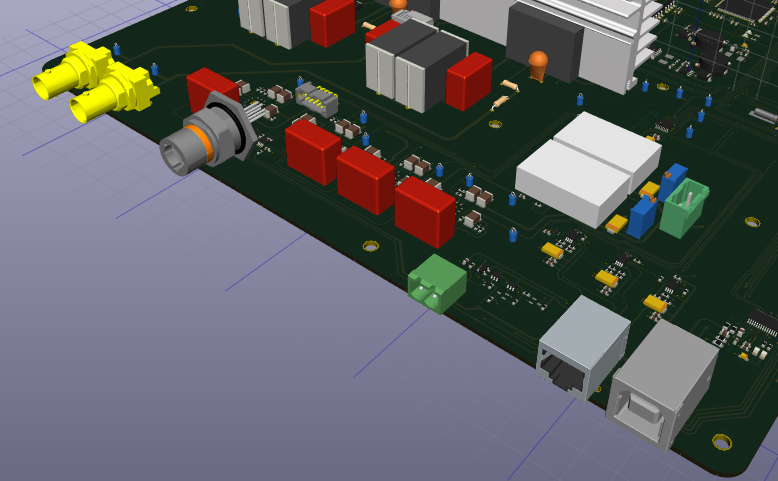

This was requ 3D view of the proposed electronic assembly (from KiCad)

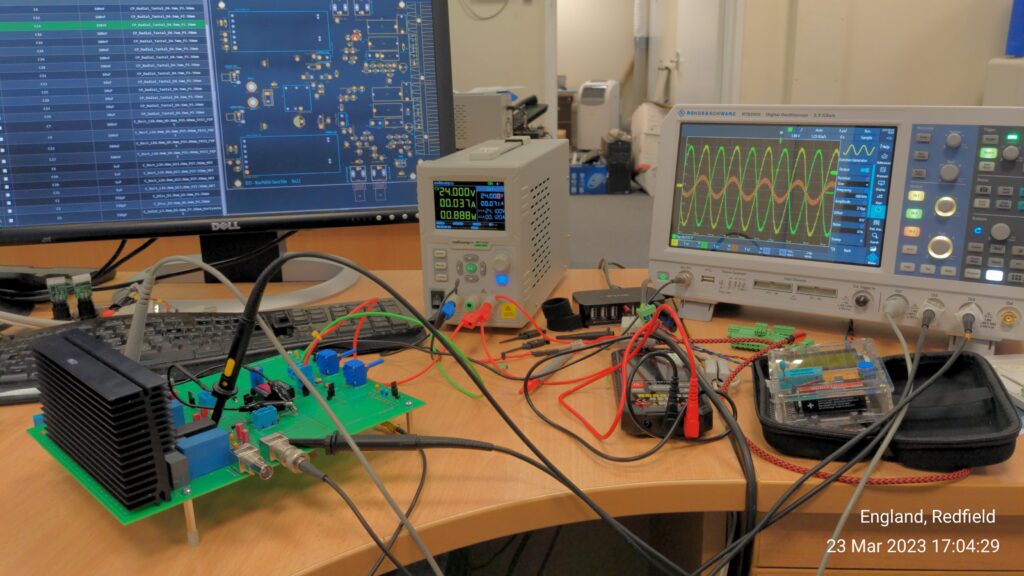

Bench tests of signals and our first prototype

This was our proof of concept and a prototypee of the initial design. It helped us understand practical challenges and thee need for optimization due to noisy switching power supplies and review of our Analog signal proccessing chain and bandwisth of our operational amplifiers in delivering pure 700 Vp_p 100KHz sinusoids with up to 100V DC offset.

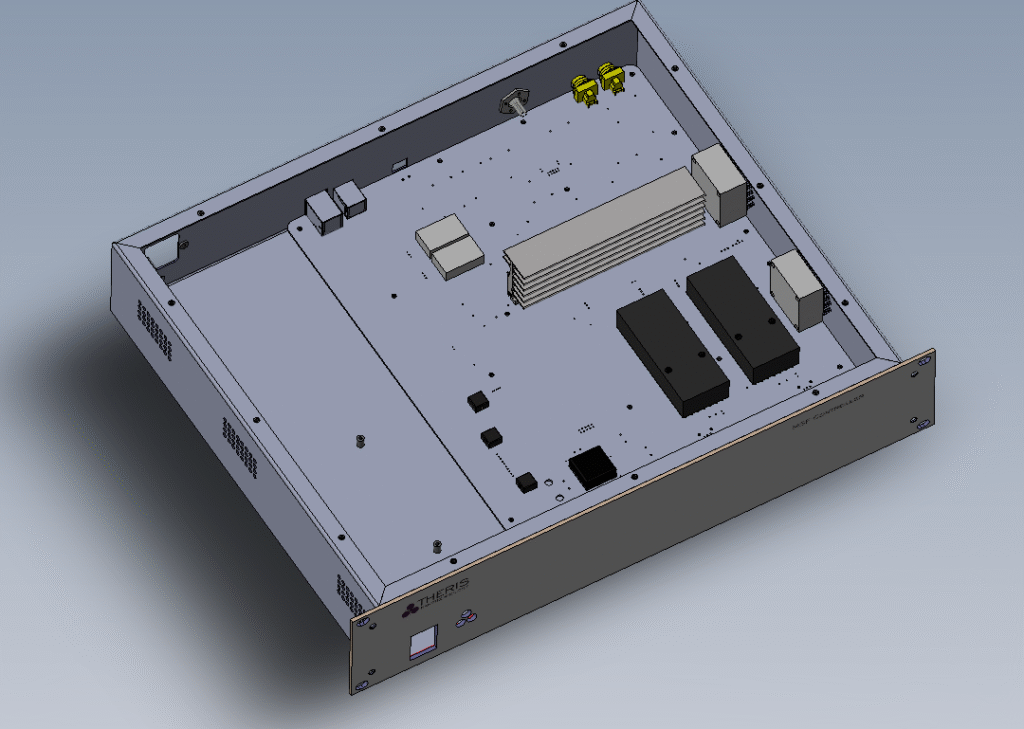

Here’s how we perceived the final product

Our optimized Revision 2 circuits and PCB resulted in meeeting stringent requirements and here it is (below) our enclosure fitting model where we identify locations of extrusions needed for the edge I/O connectors.

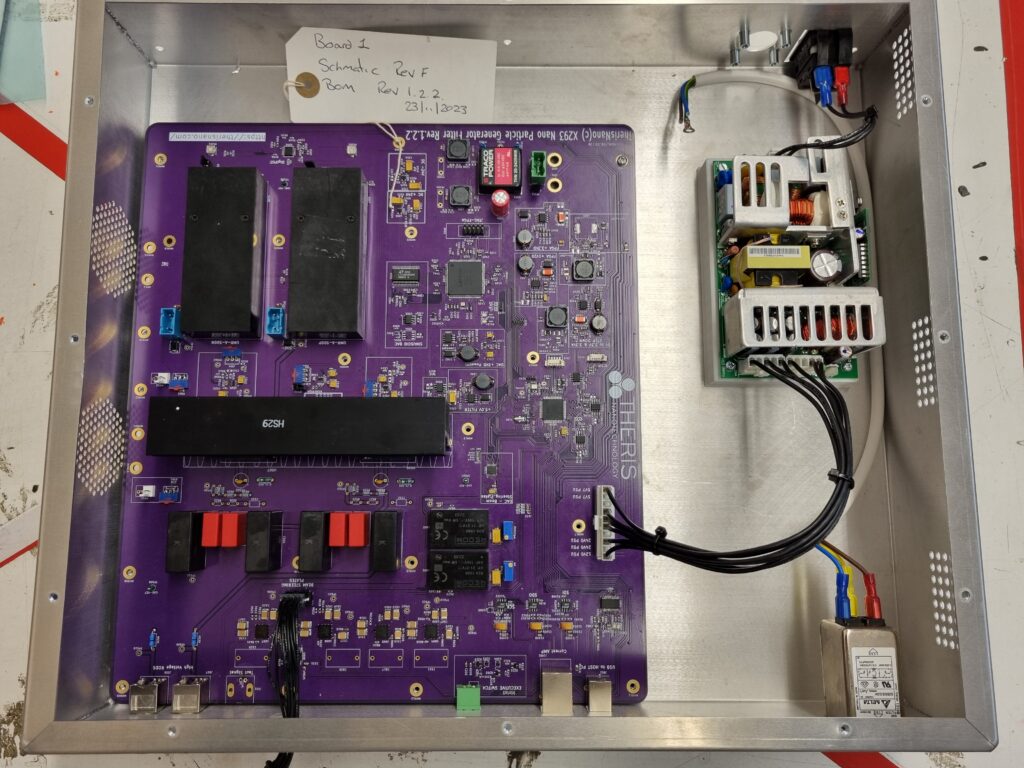

Our engineering efforts resulted in final proptotype and update of the design shown below, housed it in this semi custom 19″ 2U enclosure in preeparation for field trials.